Have a Gas Emergency?

Call 1-800-444-3130

24 Hours a Day

811 Call Before You Dig

Call 8-1-1 before you dig to have your utility lines marked for free.

Pipeline Safety Question or Concern?

Ask a question or provide feedback about Pipeline Safety.

NYSE: NFG

(Minimum 20 min. delay)

$53.57

$0.14

Volume 382,224

04/22/2024

4:00 PM

Our Commitment to Safety

The safety of our customers, employees and local communities is a top priority for National Fuel.

Pipeline Safety and Integrity

National Fuel has been building and operating natural gas pipelines for more than a century and continues to embrace a culture of “safety first.” As such, we plan maintenance efforts to meet or exceed targets established by our many regulators and invest tens of millions of dollars annually to improve the operation of our systems.

Utility Pipeline Replacement Program

National Fuel has an excellent utility system safety record. With more than 22,300 miles of pipelines, our utility system is sizable and complex. Over the years, advances in materials technologies, such as the improvement of plastic pipe design, have allowed us to further enhance system safety. Just over two decades ago, our utility segment began an ambitious program to accelerate the modernization of its system. Since that time, the company has made remarkable progress, eliminating more than 58% of its bare steel, cast iron and wrought iron mains and more than 68% of its bare steel services across the system. In Pennsylvania, the company has eliminated and replaced all cast iron pipelines.

We have recently accelerated the pace of pipeline replacement. Over the past five years, National Fuel has invested over $341 million in the safety of our utility pipeline network, including replacing approximately 754 miles of bare steel, cast iron and wrought iron utility mainlines. As a result, the company has seen a significant reduction in the number of leaks reported annually.

Pipeline Expansion and System Modernization

Since 2010, National Fuel has invested more than $2 billion installing gathering infrastructure and expanding our interstate pipeline systems to provide consumers across the Northeast with access to growing natural gas supplies that are being produced in the Appalachian shale region. Our pipeline and storage subsidiaries, National Fuel Gas Supply Corporation and Empire Pipeline, Inc., have also been leveraging these expansion projects as an opportunity to upgrade their systems. Over the past six years, the segment has invested over $366 million on modernization efforts, including replacement of aging transmission pipelines and modernization of compression facilities to employ best available technologies.

Every pipeline and natural gas-related facility is built to meet or exceed a comprehensive set of construction standards and regulatory requirements. Federal and state pipeline safety codes require that pipeline operators comply with extensive requirements for material quality, design, construction, testing, inspection, and operations and maintenance for all facilities. National Fuel meets or exceeds the requirements of all state and federal laws and regulations applicable to the construction and operation of natural gas infrastructure. In carrying out our responsibilities we value community perspective and have extensive and transparent outreach to stakeholders involved in or affected by pipeline construction activities.

Customer Safety

National Fuel places the highest priority on the safety of our customers and the communities we serve, every day of the year. From our call center representatives to construction and customer service personnel in the field, our employees are dedicated to delivering natural gas to our customers in a safe and efficient manner. National Fuel has a longstanding culture of safety that encourages continuous improvement of our performance, with demonstrated success in the following core areas of customer protection.

Leak Management

An effective leak management program is essential to ensure safety and to reduce greenhouse gas emissions from natural gas leaks. Using accelerated and targeted leak surveys, our leak management program is designed to find and repair leaks before they can become a hazard. As a result of National Fuel’s accelerated pipeline replacement program discussed above and our comprehensive leak management program, we have been able to reduce year-end leak backlogs by more than 60% over the past five years.

Emergency Response

It’s National Fuel’s belief that the most hazardous condition is the unknown condition, and that quick emergency response is critical to operating a safe utility system. We are continually evaluating our performance to ensure that we respond to all emergency calls in the shortest time possible and work to remove any impediments that could potentially slow down a first responder.

Our emergency response time is among the shortest for gas utilities in both New York and Pennsylvania. In 2021, National Fuel responded to over 96% of emergency calls in under 30 minutes throughout its New York service territory. In Pennsylvania, where our service territory is more rural than in New York, National Fuel responded to emergency calls within 45 minutes over 99% of the time.

National Fuel also utilizes remote-control valves in many of its pipelines to reduce response times for potential pipeline emergencies, with a particular focus on highly populated areas. When mainline valves are installed on large modernization projects or system expansions, those valves are equipped with capabilities that allow us to quickly cut off natural gas flows along a section of pipeline during an emergency situation.

Damage Prevention

While we cannot control the actions of all third-party excavators in our region, National Fuel dedicates significant resources to educate and train contractors, our customers and the general public on the importance of damage prevention and safe excavation practices through our 811—Call Before You Dig awareness campaign.

National Fuel averages approximately 170,000 requests for pipeline marking prior to excavation on an annual basis. As a result of our focus on public education and continuous improvement, National Fuel has achieved a 26% decrease in excavation damage rates over the last five years.

National Fuel also devotes considerable resources to leak patrol and surveillance of its high-pressure pipelines, both on the ground and in the air, to look for indications of leaks and encroachment activity by third parties.

Average Emergency Response Time (CY 2021)

NY: 96% of emergency calls responded to within 30 minutes

PA: 99% of emergency calls responded to within 45 minutes

26% Decrease in Excavation Damage Rates Over the Last 5 Years

73% reduction in outstanding leaks from Calendar Year-End 2021

Exploration and Production

Seneca Resources reinforces the goals of Environmental, Health, and Safety Mission, Vision, and Principles at every work site. In 2019, Seneca Resources employees only had one OSHA-recordable injury. Seneca Resources also continues to make significant progress in reducing preventable motor vehicle accidents. In 2019, Seneca Resources achieved a preventable motor vehicle accident rate of just 1.26 per 1,000,000 miles driven.

Employees and Contractors

Safety is a guiding principle and our highest priority at National Fuel. It’s imperative that every employee and contractor return home safely each day.

Key Worker Programs and Initiatives

Across the company, we have implemented programs and management practices to ensure that a culture of safety is prioritized and embraced throughout the whole organization. These important initiatives include:

- Operating procedures designed to help employees and contractors quickly identify and respond to emergency situations

- Regular required training and certification in the field and the office

- Construction site work rules, procedures and guidelines on personal protective equipment

- Daily “tailgate” meetings at company work locations and active construction sites that identify potential hazards and promote open communication about safety issues

- “Stop work responsibility” given to all employees and contractors in the event they observe an unsafe practice or condition

- Table-top emergency simulations

- Drills and emergency response preparedness with local first responders

- Cross-functional management audits

- Contractor safety pre-qualifications and reporting on environmental, health and safety (EHS) performance

- Vehicle programs and driver safety training, including the use and review of driver cameras

- Company-wide “Safe 4 the Right Reasons” safety culture campaign for promoting safe work behaviors and inspiring teamwork for safety

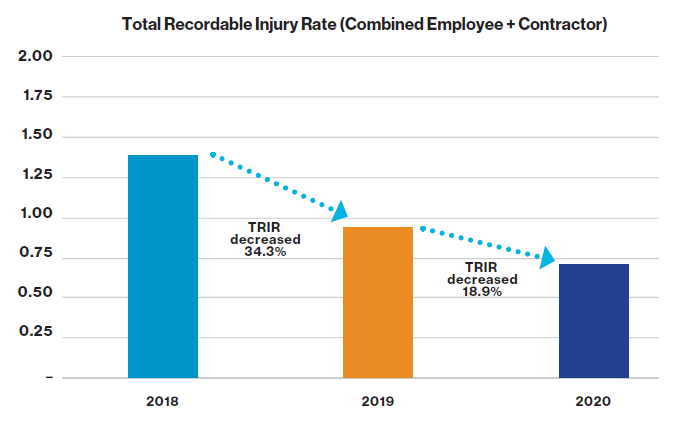

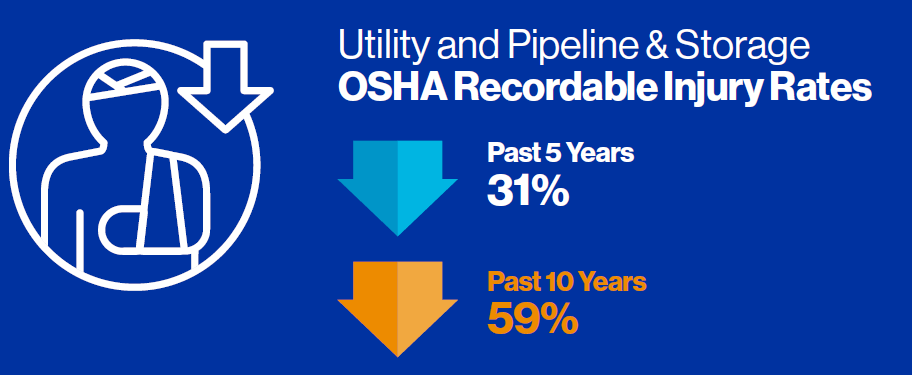

Workforce Safety Metrics

National Fuel’s workplace safety record has improved significantly over the last 10 years. We track and report safety incidents on a consolidated basis for our rate-regulated subsidiaries.

Seneca provides employees and contractors with training on near misses and regular communications to emphasize the importance of near miss reporting. In addition, safety communications highlighting significant near misses and lessons learned are shared.